To assess the quality of project planning, it must be done from a qualitative and quantitative perspective.

A qualitative assessment of the quality of planning is based on subjective criteria. For example, grouping of activities (WBS), description of the activities, number of activities, allocation of resources, logical construction sequence or if it adjusts to the reality of the project. The last one being the most important of all, since without planning realistically, it will not be possible to evaluate the real impact of the different strategies or calculate the impact of a certain event.

A quantitative assessment of planning quality is based on quantifiable criteria based on best practices defined by the industry.

There is a set of checkpoints known as the DCMA 14-Point Assessment (DCMA-14), defined by the US Defense Contract Management Agency. They are not necessarily hard and fast rules, but these indicators show how consistent a schedule is and highlight potential problem areas in planning. This evaluation offers a way to objectively check the quality of the planning, although meeting these guidelines does not necessarily mean that the schedule is feasible, not meeting them is a guarantee that it is not.

1. Logic of tasks

All tasks must have a predecessor and successor activity except the first and last corresponding to the start (NTP) and end-of-project milestones.

A task without a predecessor will not move with the rest of the activities in the event of a delay, so it can lead to shipments of material or arrival of resources, with the cost that this implies, when in reality the date start should be later.

The DCMA recommendation is that no more than 5% of planned activities may lack, at any given time, predecessor or successor.

2. Negative clearances

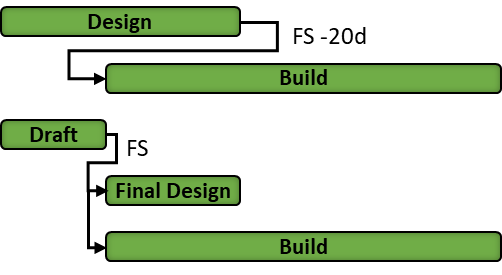

Negative floats appear on a schedule when the target completion date cannot be reached due to construction sequence changes or project delays. However, in this case the negative slack is the one existing between two tasks in which the successor starts a few days before the end of the predecessor (negative lag).

Negative slack is not allowed in any schedule, and the correct practice is to decompose activities to a level of detail where traditional FS or SS relationships can be used. The DCMA states that tasks with negative clearances should not be scheduled.

3. Delays (Positive Lags)

Delays or lags in the start of activities should be avoided because they can negatively affect the analysis of the critical path of the project. In addition, they can create confusion if the reasons that lead to their use are not perfectly justified.

Instead of adding a delay to the start of a certain activity, it is recommended to represent that time by means of another activity, for example, if certain days must be waited for the setting of the foundations to start the next activity, it is recommended to represent that drying time as a independent task.

The DCMA sets the limit at 5% of relationships with positive lag.

4. Relationship types

There are basically four types of relationships:

- FS (Finish to Start)

- SS (Start to Start)

- FF (Finish to Finish)

- SF (Start to Finish)

The ideal relationship between the activities of a project is the Finish to Start relationship, since it allows defining a clear sequence and an easy-to-understand critical path is generated.

The DCMA maintains that at least 90% of all relationships between tasks must be from Finish to Start. There may be specific cases where Finish-Finish and Start-Start relationships are appropriate, although they should be kept to a minimum. In case of exceeding 10% of relationships of this type, it is recommended to evaluate the level of detail of the schedule.

5. Rigid Constraints

Constraints allow scheduling the start or end of an activity without taking into account the existing relationships, it being recommended that the dates be the natural result of the dependencies and the duration of the activities.

If necessary, soft restrictions of the start-no-previous type should be used since they allow the date to continue being directed by logic and in no case use “mandatory” since it is a type of restriction with maximum priority, so relationships and calendar will be ignored.

DCMA’s proposed threshold for hard constraints is no more than 5% of planned activities (to be executed) in the project schedule.

Ideally, there should be no rigid constraints on planning the schedule of activities. It is best to use deadlines or slacks in schedule planning dates to represent contractual or other commitment dates that “must” be considered as “hard” commitments.

6. Maximum Clearance

Planning software allows calculating the total float of all activities, those activities on the critical path will have a float of 0 days. The DCMA marks the maximum slack as 44 days since activities with such large slack are often the result of a lack of dependencies between activities.

Do not exceed 5% of activities that exceed the maximum clearance.

7. Negative Clearances

Negative Floats occur when the project schedule is planned with a deadline or when there are rigid constraints that artificially modify the calculation of dates. Negative clearances should not occur in any project activity.

8. Maximum Duration of Clearances

The DCMA limits to 5% the number of activities with total float of more than 44 working days, approximately two months. If the activities have very large total float it is likely that they are not related correctly, giving rise to unstable logic.

The tasks or activities that are planned with gaps greater than 44 days make it difficult to objectively estimate the resources and evaluate the performance of both the schedule and the programmed cost.

9. Invalid dates

An activity is considered to have an invalid date when its start or end date has been scheduled outside the project calendar, for example, if activities are not scheduled to be carried out on Sundays, it makes no sense for the scheduled start date of a task to be a Sunday. The same is true for dates after the completion of the project.

All projects must clearly define the execution schedule taking into account the different contractors and work fronts, since they can differ considerably. The following must be defined:

- Business Days.

- Holidays or non-Working Days (may change depending on the country).

- Working hours, can be 8 hours, 10 hours, 12 hours, 24 hours depending on how many shifts are worked.

No invalid dates should be allowed.

10. Resources

In order to carry out any activity, the use or consumption of some resource is necessary, be it human resources (man hours), material resources (units, m3) or/and machinery and tools.

Depending on the nature of the activity in question, it will include one, some, or all of the resources listed above. Ideally all tasks should have some resource assigned to them.

11. Tasks not executed (lost)

It represents the percentage of tasks not completed on time with respect to the date defined in the baseline for those same activities. It could be considered a measure of the delay of a project with respect to its baseline. The DCMA threshold for unexecuted or lost tasks is 5%.

12. Test or Critical Path Test

The critical path is defined as the sequence of activities with a margin of delay (slack) equal to zero. Therefore, the critical path is the longest continuous sequence of activities of the Project, which implies that a delay in any of the these activities results in a delay in the Project completion date.

Once the critical path is identified, slack is intentionally introduced into the schedule by a large variation in the remaining duration of some activity on the critical path. To consider the test approved, it must be observed that the completion of the project has also been delayed and there are no negative clearances.

13. Critical Path Length Index (CPLI)

The Critical Path Length Index (CPLI) is a measure of the efficiency of the planned schedule and indicates how realistic the project completion date is.

It is defined as the sum of the remaining project duration time (number of work days planned on the current critical path) and the total float, divided by the project duration. The total slack in this case is the difference between the planned finish date and the baseline project finish date.

DCMA considers that a CPLI less than 0.95 is an indicator of a possible problem or deviation in planning that should be studied.

14. Baseline Execution Index (BEI)

The Baseline Execution Index (BEI) is another indicator that helps to understand how well tasks are being executed compared to the baseline, it measures the performance with which the project team is performing tasks.

It is calculated by dividing the total number of completed tasks by the total number of tasks that should have been completed according to the baseline for that cut-off date. An BEI below 0.95 is indicative of a potential problem that needs to be looked at.